Buhler420e Pellet Mill Die/ China Factory Agriculture Products Pelletizer Machine Parts Hotselling Ring Die For Animal Feeds Rabbit Feed

Buhler420e Pellet Mill Die/ China Factory Agriculture Products Pelletizer Machine Parts Hotselling Ring Die For Animal Feeds Rabbit Feed

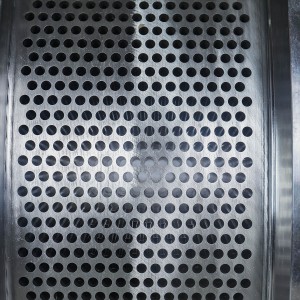

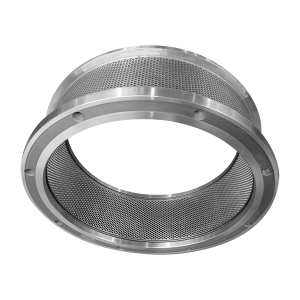

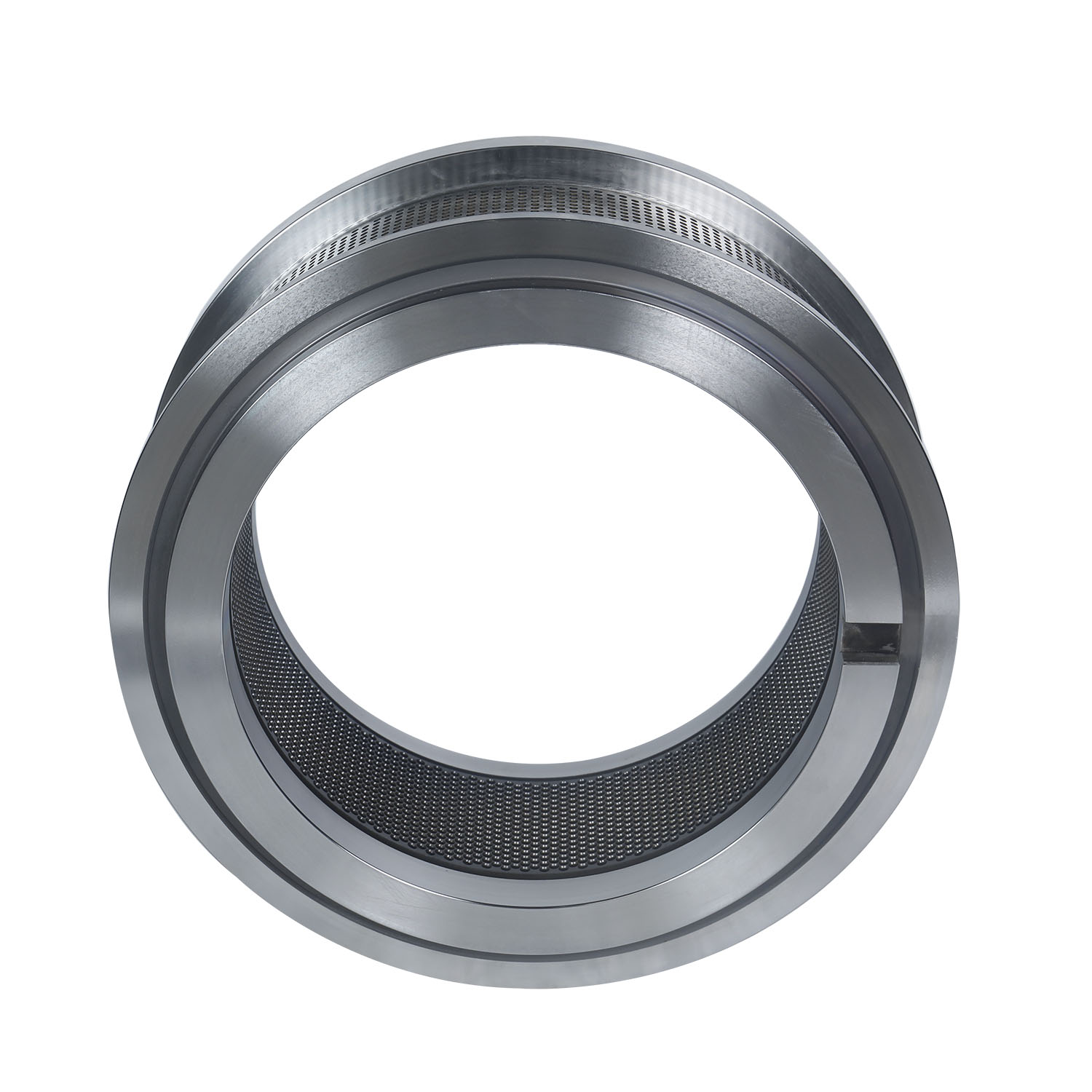

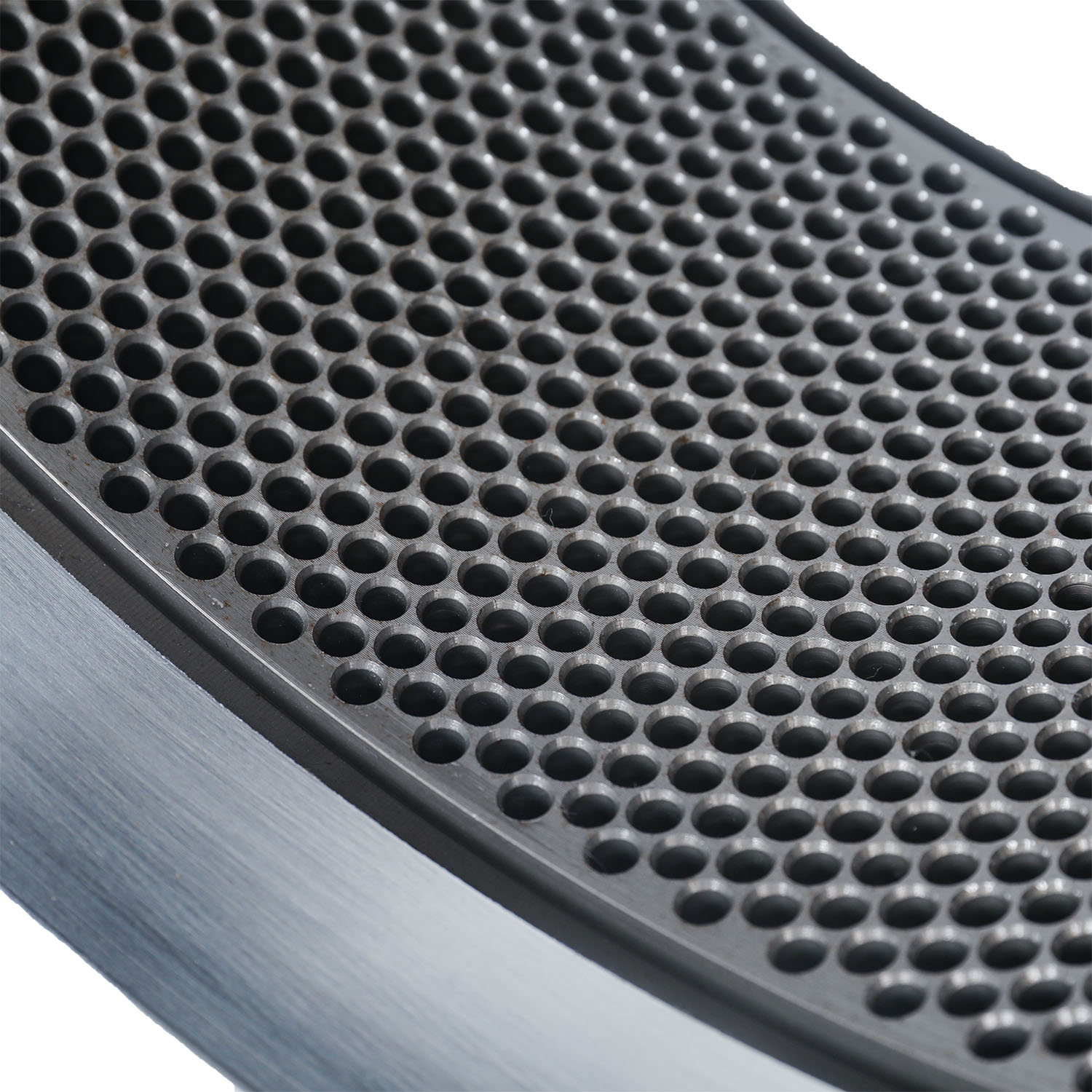

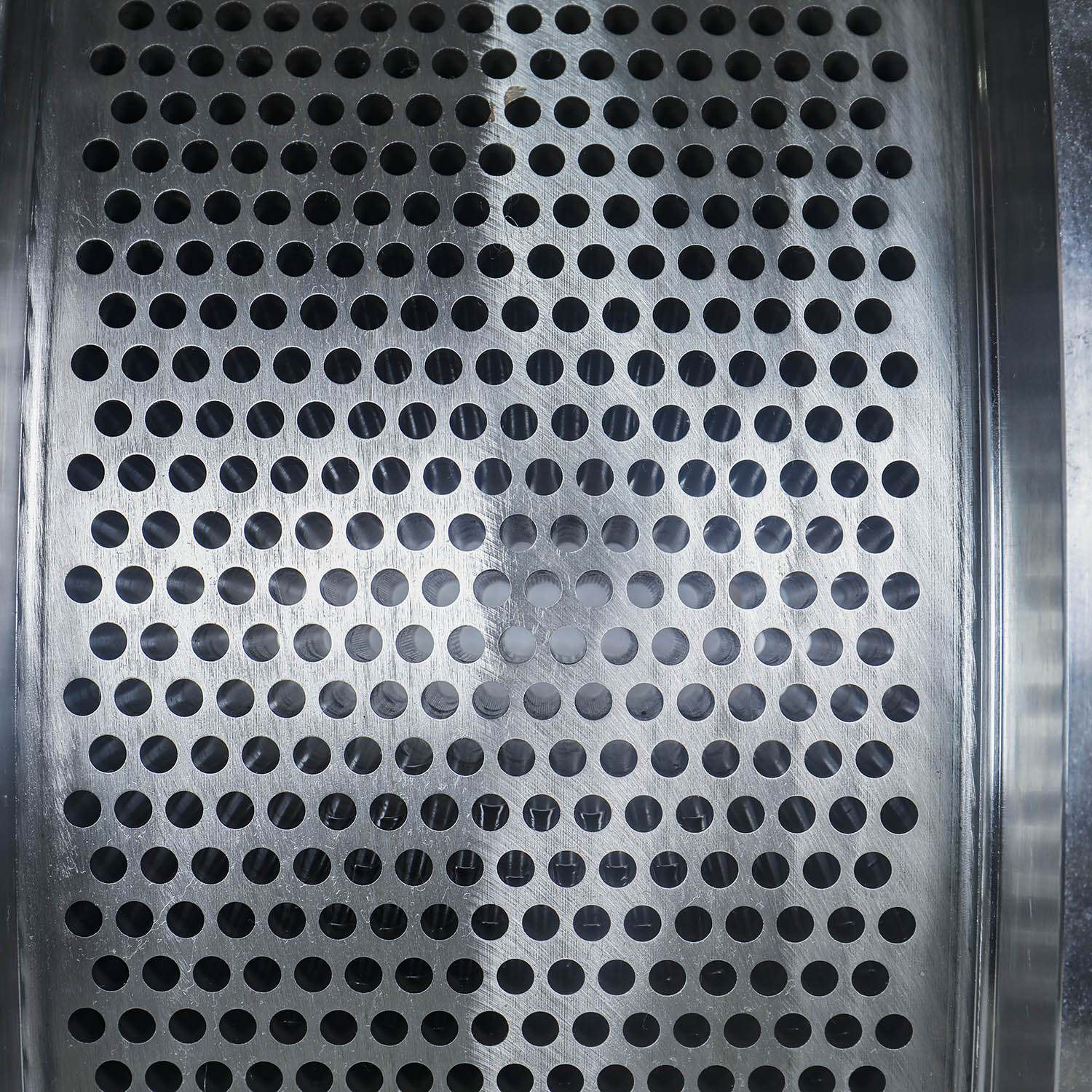

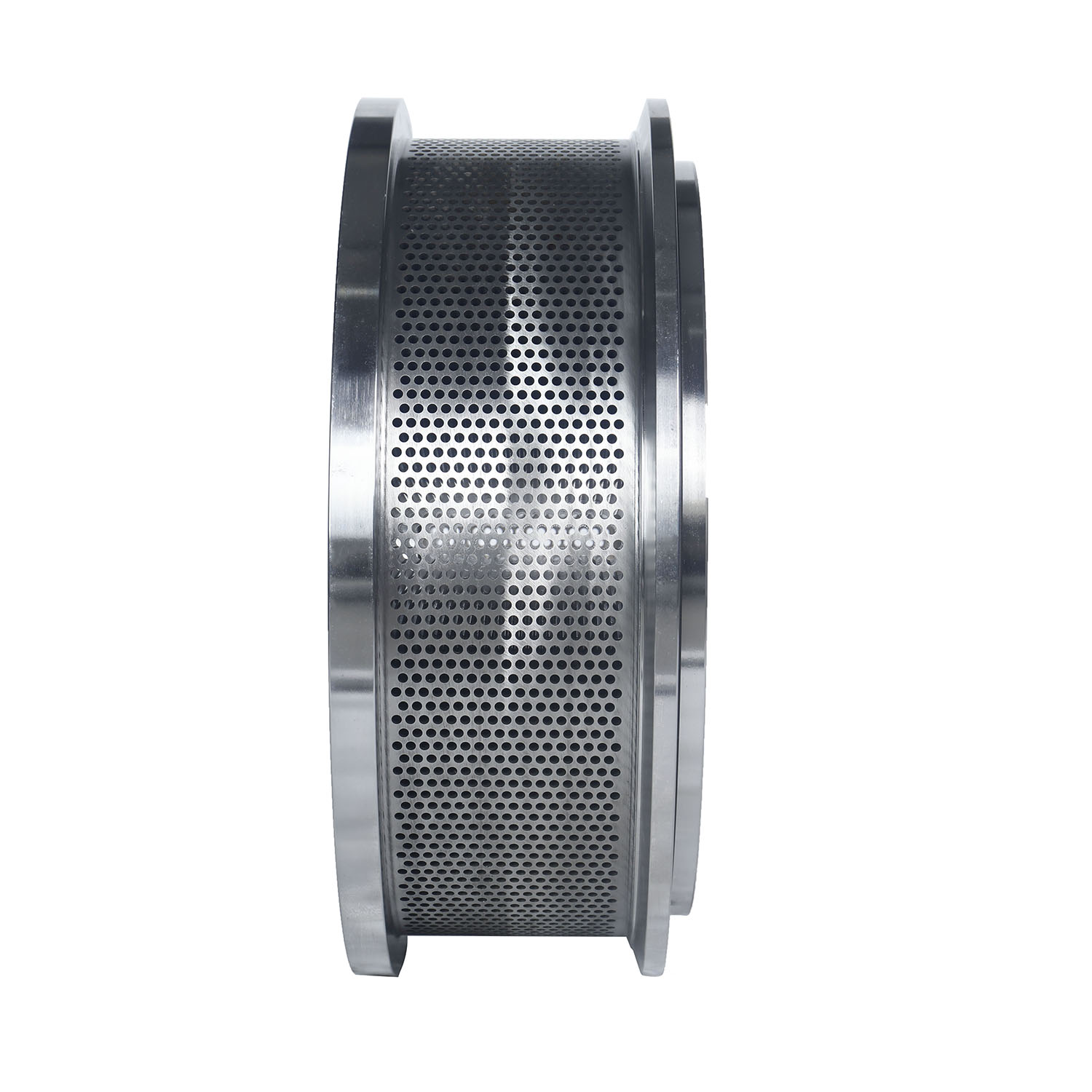

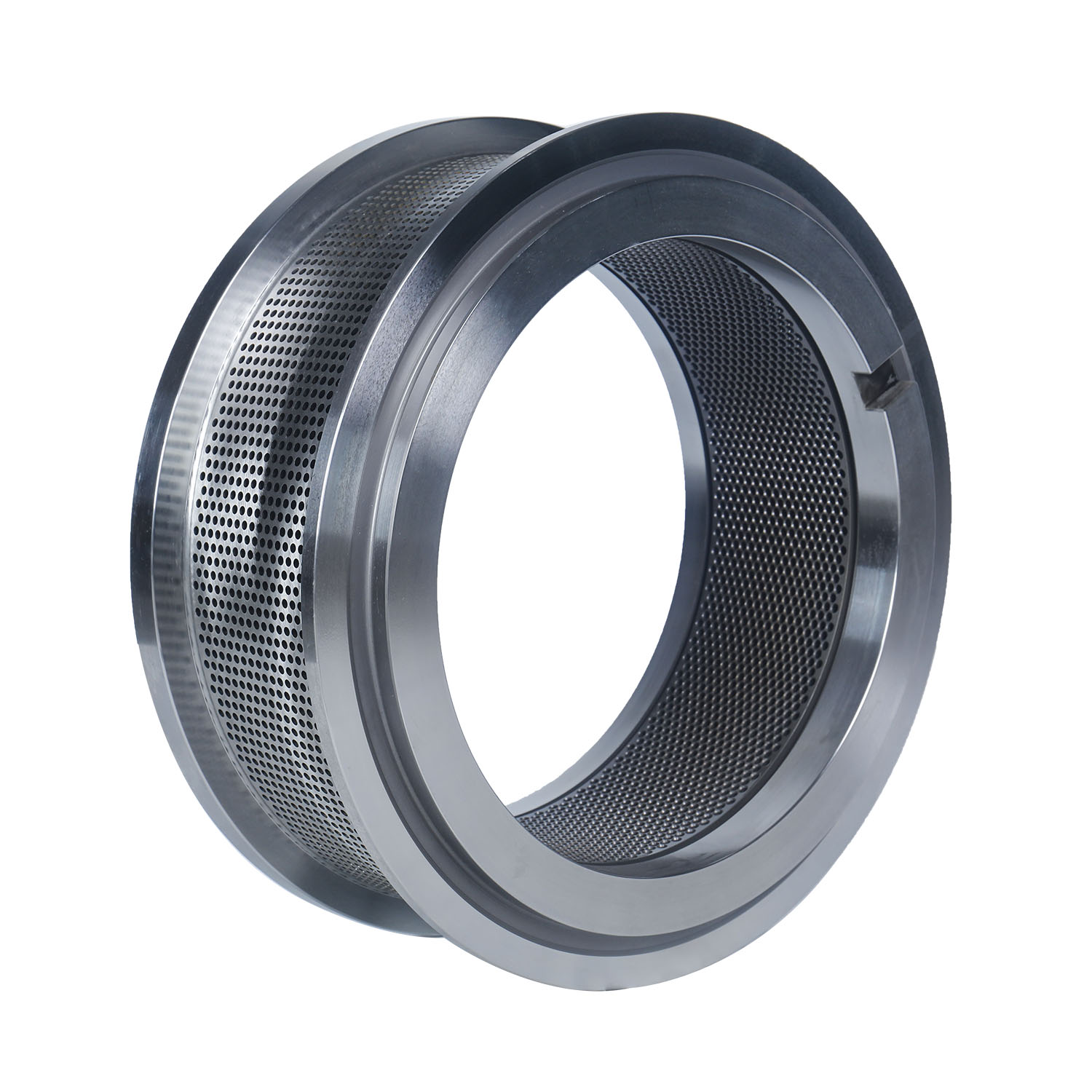

Rabbit feed pellet mill die, aperture generally be 2.5-4.5mm , compression ratio is between1: 6-1:12, because the fiber content is high, so the rabbit feed pellet production output is not high, ring mold is easy to wear.

Happy Mould use high quality X46Cr13 stainless steel, the stiffness and toughness of this material are very good.After heat treatment, its surface hardness can reaches HRC52-55 and hardness is uniform, which has good wear resistance and corrosion resistance, long service life.Then the contradiction between production efficiency and pellet quality, and the contradiction between opening rate and service life of ring die are solved effectively.So Happy Mould are high hourly feed production, good pellets quality and low powder content. Compound hardening process can also be used to improve the service life of the pellet mill die.

Ring die working maintenance

1. Due to the different varieties of feed production, which involves the different ring die material, opening rate, inner cone hole, die hole length and release hole, enterprises with advanced professional technology should be found to design and customize different process ring die based on feed raw materials and actual use, so as to ensure the use value of ring die play.

2. The clearance between the roller shell and the ring die should be controlled in 0.1-0.3mm. Do not let the eccentric roller shell contact the surface of the ring die or one side of the clearance is too large.This size is not visible to the naked eye during installation,avoid to cause increased wear of the ring die and roller shell or non-discharge phenomenon.

3. When the pellet machine starts, the feeding quantity is changed from low speed to high speed. Do not run at high speed at the beginning, which will cause damage to ring die and pellet machine due to sudden overload or ring die blocking.

X46Cr13 stainless steel pellet mill die

ring die for making rabbit food

rabbit food pellet making machine

rabbit feed pellet mill die