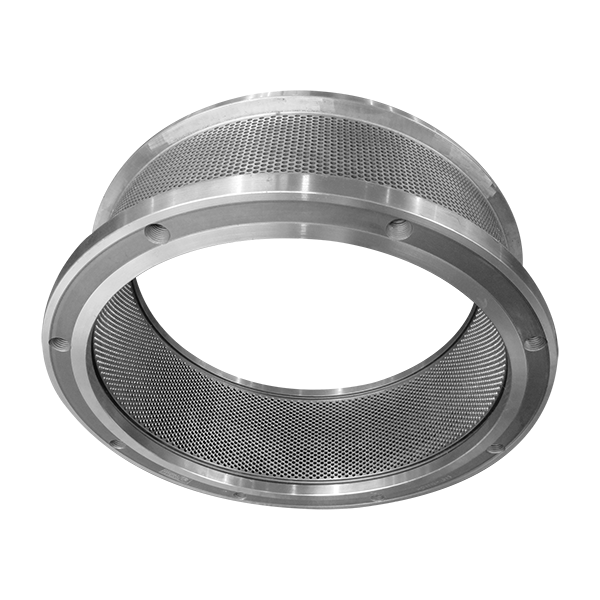

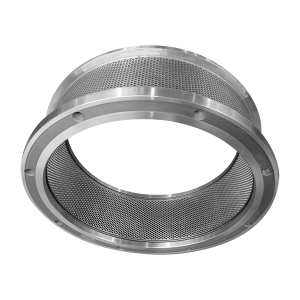

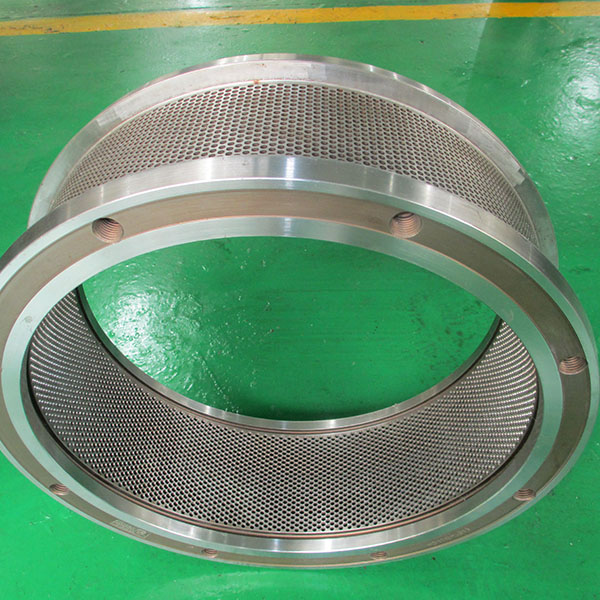

Pellet mill die for pig feed / Professional Manufacturer Directly Supply

Pellet mill die for pig feed / Professional Manufacturer Directly Supply

As a key equipment in the feed production process, the heart of the pelletizing machine is the ring die (Zhengchang, Muyang, Shende), which is also one of the most easily worn parts in the pelletizing machine. For feed producers, it is urgent to reduce production costs and improve feed pellet quality, which is largely determined by the quality of ring die. Hanpai pig feed pellet mill die using high quality stainless steel material to ensure the long service life of the ring die, the use of CNC deep hole drilling on the die hole processing to ensure the die hole smooth, avoid forming the crooked hole, so as to achieve the ring die fast discharge, good pellet quality and other characteristics; After vacuum heat treatment, the high wear resistance and high strength of the ring die material are guaranteed, and the smoothness of the die hole is effectively protected.

Because the fodder is not conducive to eating, the Happy Mould decompresses the feed through making two or more step release holes to reduce the amount of feed compression in order to avoid the feed is too squeezed. The suitable compression ratio can reduce the hardness then texture can be loose , which is convenient for suckling pigs to eat.

The procedure for removing the ring die shall be as follows:

(1) Before replacing the ring die, ensure that the power of the pelletizer is cut off. Adjust cutter away from ring die and open granulation chamber.

(2) Remove the rotary feed cone.

(3) Increase the clearance between the roller and the ring die.

(4) Slightly tighten the wire rope to lift the hanging part of the ring die lifting device with the ring bolt hole and bolt fixed.

(5) Remove the bolts, straps and fasteners from the hoop in the granulating chamber.

(6) Remove the ring mold along the width of the press roll with the lifting device, and then start the motor, and slowly put the outer mold on the ground.

(7) After removal, check whether the scraper on the front bracket wears the ring die excessively.

4.5mm hole size pig feed pellet making machine

pig feed machinery

pig feed pellet mill machine

pig feeding equipment pellet mill die

pig feed production line pellet mill die

pig feed pellet mill machine

pig feed pelletizer machine Famsun 420TW-4.5--1

Apply For FamsunV6 for making pig animal feed