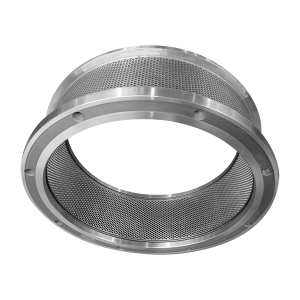

Injin Granulator Bio Taki / Babban Na'ura Ya Mutu Pellet Mill Ya Mutu Daga China

Injin Granulator Bio Taki / Babban Na'ura Ya Mutu Pellet Mill Ya Mutu Daga China

Tsarin taki ya ƙunshi takin gargajiya, taki, ma'adinai da sauransu.A inorganic taki a fili taki, kamar urea ne m ga zobe mold, da zobe mutu rami da ciki mazugi rami suna sa mai tsanani da ma'adinai, don haka kayan na zobe mold ya kamata a zaba bakin karfe X46Cr13.Compound taki zobe mutu budewa ne kullum babba, kewayon tsakanin 3.0-6.0mm, saboda da babban gogayya coefficient, da rami da wuya a fitarwa, don haka da matsawa rabo ne karami, kullum tsakanin 1:4-1:6.A lokaci guda, saboda takin mai magani yana dauke da kwayoyin cuta, zafin jiki ba zai iya wuce digiri 50-60 ba, in ba haka ba za a iya kashe maganin a cikin sauƙi.Saboda haka, fili taki bukatar low granulation zazzabi, da zobe mold kauri ne general zama bakin ciki.Saboda fili taki lalacewa tsanani zuwa zobe mutu rami, yana da sauki toshe inji a samar, da kuma tsanani lalata zobe mutu, wanda kai tsaye rinjayar samar da inganci da kuma sabis na zobe mutu.Happy Mold yana amfani da tsari na musamman na samarwa da jiyya na ƙasa don haɓaka ingantaccen samarwa da rayuwar sabis na ƙarshe na injin pellet ɗin taki ya mutu.

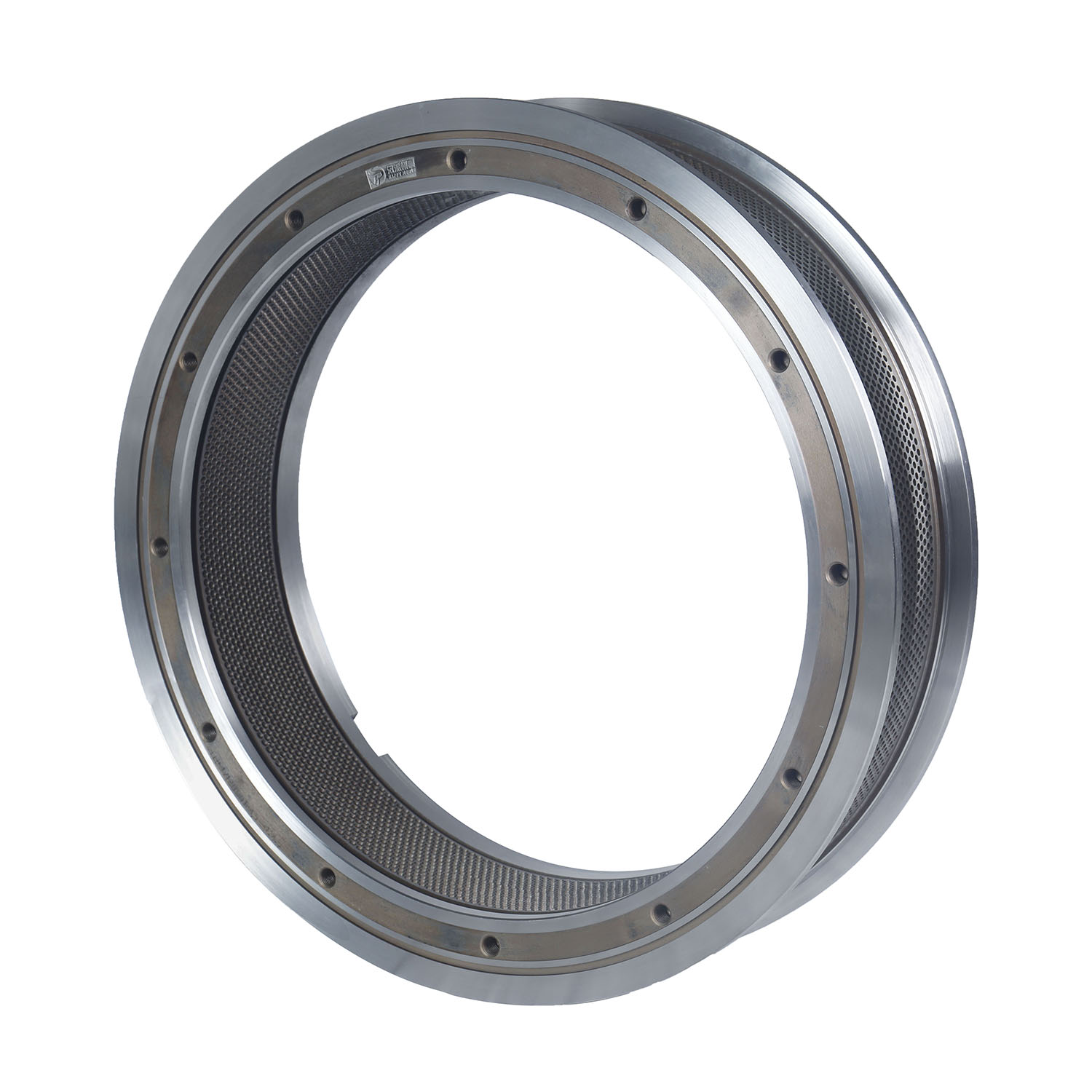

Menene ƙimar buɗaɗɗen ramin pellet mutu?

Pellet niƙa mutu adadin buɗewa = [(R/2) 2×π × n] / zobe mutu wurin aiki(Da'irar ciki na innercircle na pellet mutu da latsa rubutun extruded juna shine fuskar aiki na zobe mutu. )

R: Girman ramin zobe mutu, n: jimlar adadin ramukan mutuwar zobe

Daga wannan dabara, zamu iya fahimtar cewa lokacin da aka ƙayyade girman ramin, yawancin ramukan da ke cikin zobe suna mutuwa, mafi girman ramin buɗewar zobe ya mutu.

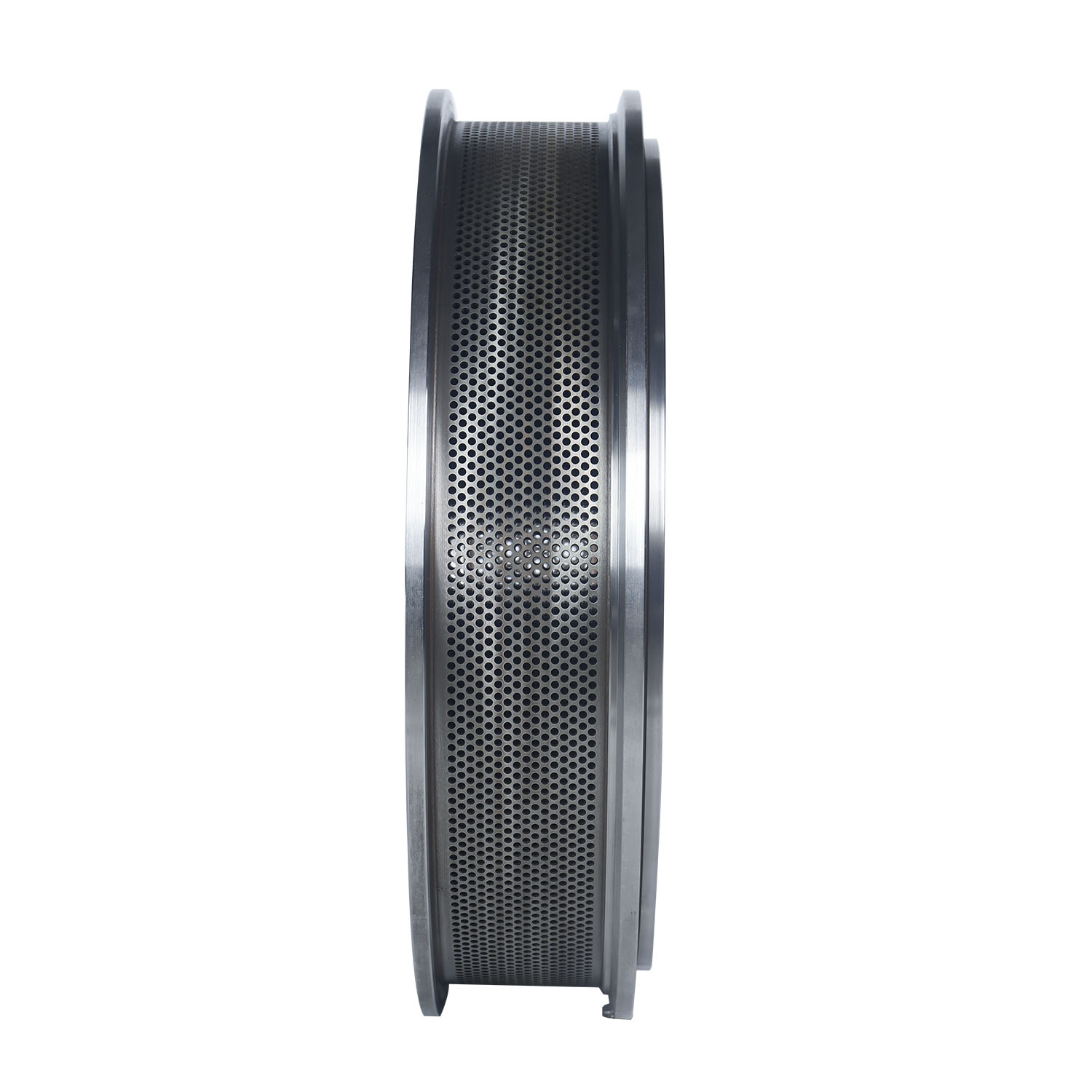

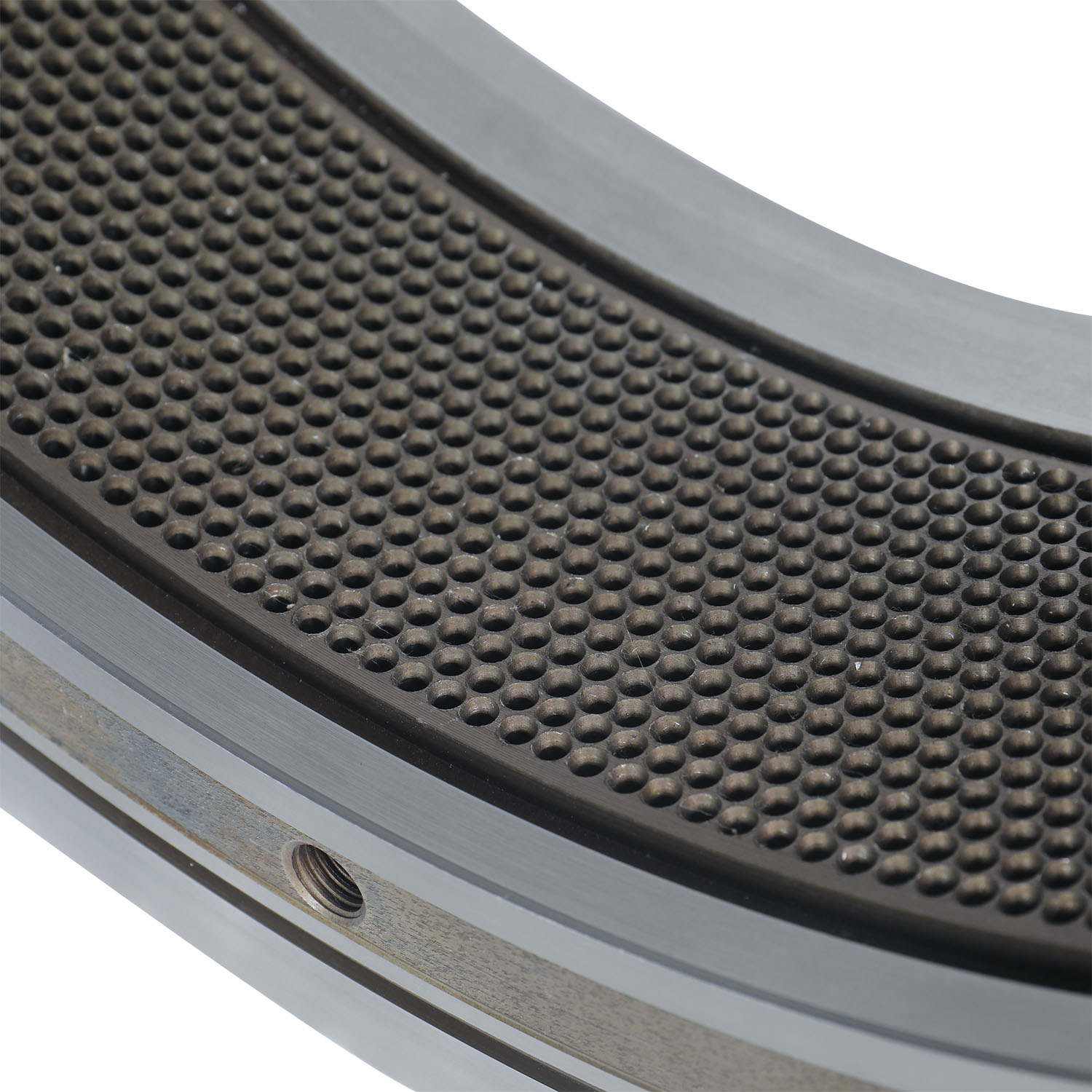

Menene ramin saki?

Ramin daɗaɗɗen da diamita ya fi girma ɗan ramin pellet kuma an rarraba shi daidai a saman kewayen injin pellet ya mutu.

Lura: Lokacin da matsi rabo ninka da budewa ba zai iya kai ga mafi ƙarancin ƙira kauri na zobe mutu, da zobe mutu kauri dole ne a ƙara don saduwa da aminci bukatun na zobe mutu.The ƙãra part na zobe mutu kauri dole ne a sarrafa cikin. saki ramukan.

kwayoyin taki kajin taki pellets

kaji taki taki pellet niƙa mutu

Organic taki pelletizer

China Kera Granulator Ring Die