masana'anta kai tsaye suna ba da kayan sarrafa kayan agro pellet niƙa kayan aikin abin nadi harsashi

masana'anta kai tsaye suna ba da kayan sarrafa kayan agro pellet niƙa kayan aikin abin nadi harsashi

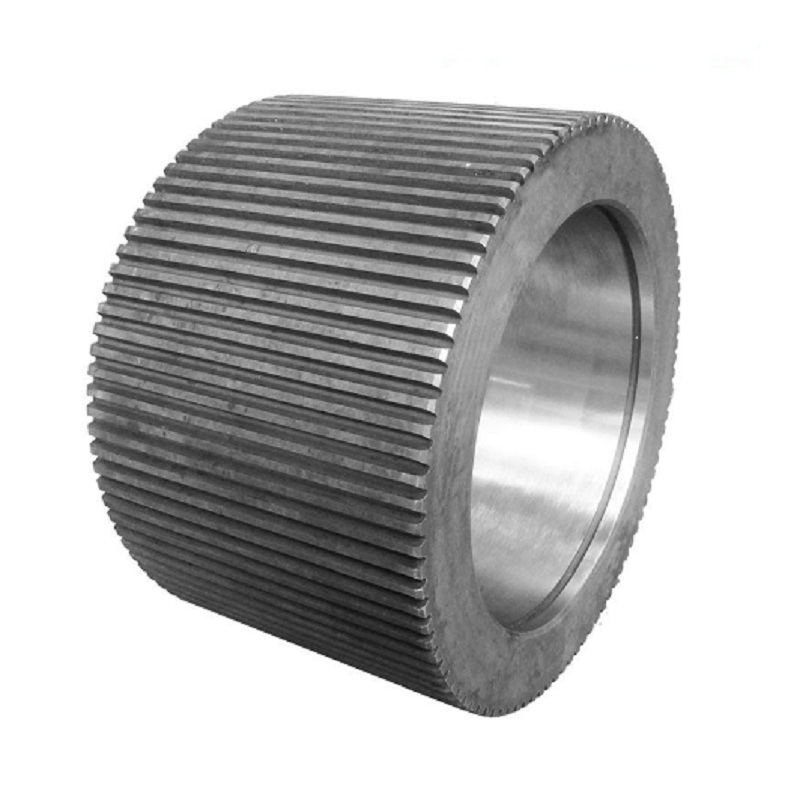

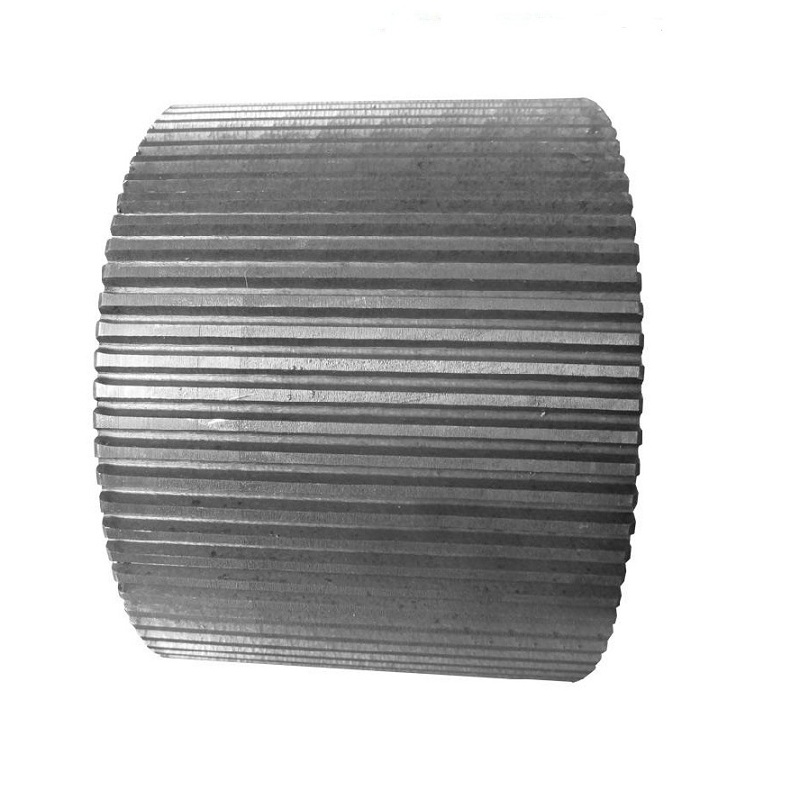

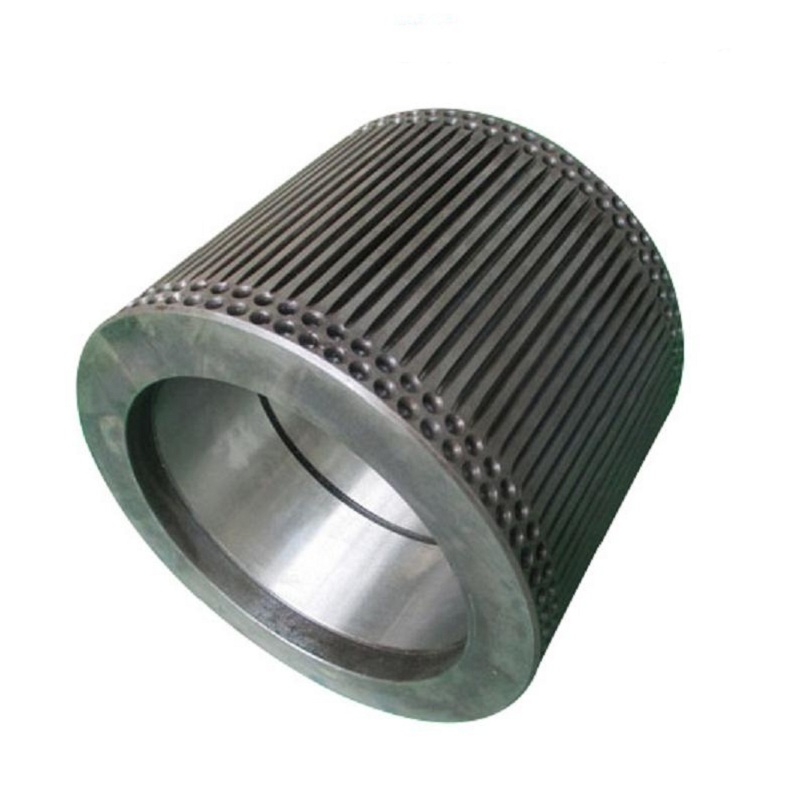

Kamfaninmu na nadi harsashi da aka yi da high quality abu da kuma musamman zafi magani sarrafa.Its surface ne mafi wearable da taurin ne uniform, hade tare da Happy Mold zobe mutu, sabis rayuwa zai zama ya fi tsayi, sa'an nan yin samar da aminci da smoother. Yanzu akwai ta hanyar tsagi irin, m tsagi irin, biyu ƙare tare da ramukan irin da sauran. iri.Mai girma dabam da kuma siffofi na rollers za a iya musamman bisa ga bukatar mai amfani.

Ƙayyadaddun sigogi na abin nadi:

Abu: Gcr15 ko 40Cr 20CrMnTi

Outer diamita na workpiece: Ø300mm-1200mm

Taurin saman: HRC 58-62

Hakora sararin samaniya da siffar: Dangane da bukatun abokin ciniki

Hanyar da ta dace ta amfani da kashe zobe da abin nadi

1. Daidaitaccen zaɓi na ramin mutuƙar zobe da ya dace da ƙimar matsawa.

2. Daidaita daidaitaccen rata na aiki tsakanin zobe mutu da latsa yi, tsakanin 0.1 ~ 0.3mm ya dace.

3. Ya kamata a yi amfani da sabon zoben mutun tare da sabon harsashi.Harsashin abin nadi ya kamata ya zama sako-sako kafin kuma ya matse bayan ya yi daidai da zoben ya mutu.Lokacin da kusurwoyi masu kaifi suka bayyana a ɓangarorin biyu na abin nadi, ya kamata a sassauta ɓangaren flange na littafin nadi tare da injin niƙa a cikin lokaci, don sauƙaƙe daidaitawa mai kyau tsakanin mirgina da zobe ya mutu.

4. Dole ne a sarrafa albarkatun ƙasa kafin shigar da granulator ta hanyar tsaftacewa na farko da kuma rabuwar maganadisu don rage matsi da baƙin ƙarfe a cikin rami mai mutu.Da kuma duba ramin mutuwa akai-akai don ganin ko akwai wani abin toshewa.Cire ko fidda rami da aka toshe cikin lokaci.

5. Ring mutu jagora mazugi rami filastik canji kafa shrink ya kamata a gyara, gyara kamata kula da ciki surface na zobe mutu aiki a mafi ƙasƙanci batu ya zama mafi girma fiye da kasa na tsagi 2mm, kuma bayan gyara akwai har yanzu a latsa juzu'in daidaita madaidaicin shaft, in ba haka ba ya kamata a goge zoben zoben.