ʻO ka moʻolelo o ka hui

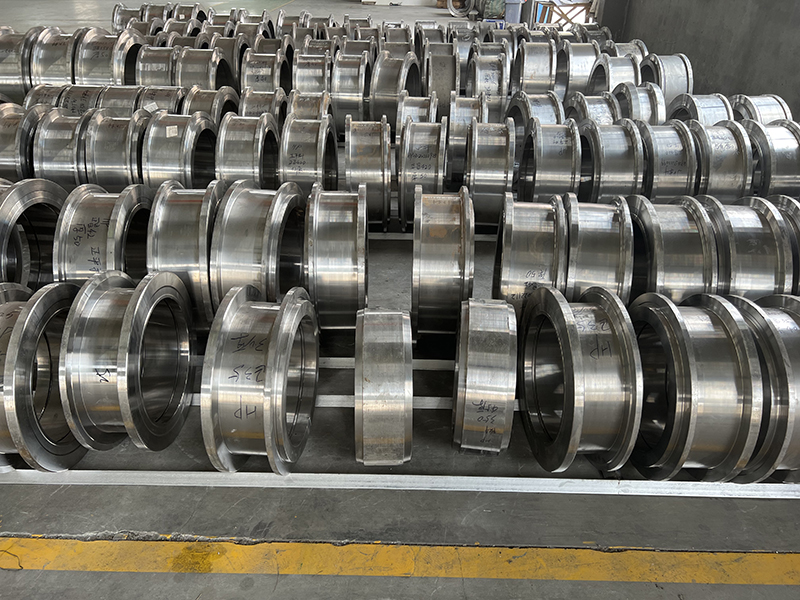

Hoʻokumu ʻia ʻo Hangzhou Hanpai Mold Technology Co. Ltd. i ka makahiki 2012, ʻo ia ka lālā o ka ʻaha kūkā o Zhejiang Die & Mould Industry Association. Hoʻolaha mākou i ka R&D a me ka hana ʻana i nā ʻāpana mīkini pellet mill, e like me ka hānai pellets apo make, biomass pellets apo make, organic fertilizer pellets make ring, pellets litter cat ring die,roller shell a pēlā aku.Hāʻawi i ka wili pellet zero defect no ka honua kā mākou pahuhopu hoʻomohala.

I ka makahiki 2017, ua hoʻohanohano ʻia mākou e like me ka ʻoihana ʻenehana kiʻekiʻe ʻo Hangzhou a hāʻawi i ka ʻae ʻia o nā ʻoihana ʻepekema a me ʻenehana ʻo Zhejiang.I ka makahiki 2018, ua hoʻololi ʻia ka inoa o kā mākou hui mai Hangzhou Hanpai Mold Co., LTD i Hangzhou Hanpai Mold Technology Co., LTD. ʻO mākou ka mea hoʻolako ʻia e SGS, i kēia manawa ua loaʻa iā mākou ka palapala ʻōnaehana hoʻokele maikaʻi ISO 9001.

Hoʻohana ʻo Happy Mold i ke kila kila kila X46Cr13 kiʻekiʻe, CNC hohonu hole drilling machine, vacuum quenching furnace, nā mea hana ʻē aʻe a me nā kaʻina hana kūikawā;I ka manawa like, loaʻa iā mākou kahi pūʻulu o nā ʻenehana kiʻekiʻe a me ka ʻōnaehana mana o ka hana ʻana, e hana ana i ka Happy Mold maikaʻi loa a me ka maikaʻi o ka mea kūʻai aku. -40%

Hauʻoli Mold

ʻO "HAPPY MOULD" kā mākou hōʻailona, me ka hoʻohana ʻana i ka Happy Mold hiki ke mālama i ka mea kūʻai aku i ka nui o nā kumukūʻai hana, hoʻonui i ka loaʻa kālā a me ka hoʻokūkū mākeke ma muli o kāna hana maʻalahi, maikaʻi pellets maikaʻi, kiʻekiʻe ka hana pono, haʻahaʻa haʻahaʻa, a me ka hana maʻalahi. hiki ke hōʻemi i ka hana ikaika o nā limahana, e lawe mai i ka hauʻoli no kēlā me kēia.

Ua lanakila ʻo Hanpai Mold i ka mahalo nui mai nā mea kūʻai aku ma ka home a ma waho, a ke kakali nei mākou i ka hāʻawi ʻana i ka maikaʻi maikaʻi a me ka zero defect mold no nā ʻoihana hana pellet honua.

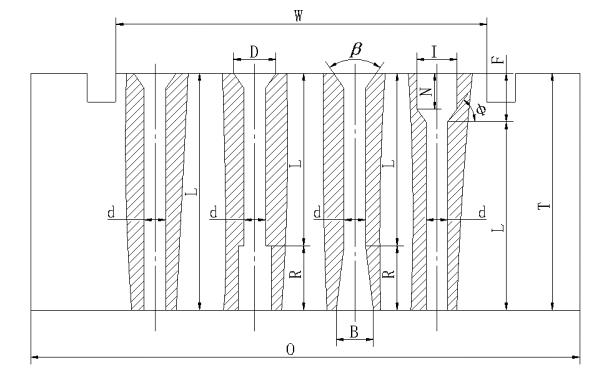

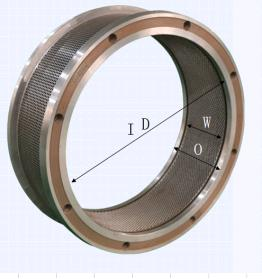

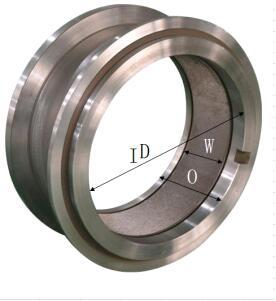

ID ma ke kiʻi -- ke anawaena o loko o ke apo make;

O -- ka laula piha o ke apo make;

W - ka laula o ke apo make (ka laula o ka ili hana);

d -- ka puka o ke apo make (ka nui o ka puka o ka pellet kaomi);

L -- ka lōʻihi o ka lua make;

T -- ka huina mānoanoa o ke apo make;

D -- ke anawaena puka komo o ka lua make;

β -- die hole conical inlet Angle;

ʻO ke ʻano o ka puka o ka wili pellet: ʻo nā ʻano puka maʻamau i hoʻohana ʻia me ka puka pololei, ka lua ʻanuʻu hope, ka puka reaming o waho a me ka puka hoʻololi i mua me ka cone.He mea maʻalahi ka hoʻohana ʻana i ka puka pololei, ka hoʻohana maʻamau;ʻO ka lōʻihi maikaʻi o ka lua make a me ka manawa extrusion mea i loko o ka lua make e hoʻemi ʻia e ka lua kuʻekuʻe hope a me ka lua taper waho, kūpono ia no ka hoʻoponopono ʻana i nā pellets me ke anawaena ma lalo o φ10mm.ʻO ka puka reaming maikaʻi me ke ʻano conical he kūpono ia no ka hoʻomaʻamaʻa ʻana i ka meaʻai pellet i ʻoi aku ke anawaena ma mua o φ10mm me ka nui o ka fiber crude content.Ma waho aʻe o nā ʻano ʻano puka he 4 i luna, aia nā ʻano puka like ʻole, e like me ka puka conical o waho, ka lua cone i loko a me ka puka pōʻai ʻole, akā ʻaʻole maʻamau ka hoʻohana ʻana.

R -- ka hohonu o ka hoʻohuli hou ʻana (puka hoʻomaha kaomi);

B -- ke anawaena o ka hoʻohuli hou ʻana (puka hoʻomaha kaomi);

φ -- kihi hoʻololi reaming maikaʻi;

F -- ka hohonu reaming maikaʻi;

I - ke anawaena reaming maikaʻi;

L/d -- ka lōʻihi-aperture ratio (pākuʻi lākiō).

ʻO ka mānoanoa o ka pellet mill make (T): ʻO ka mānoanoa o ke apo make e pili pono i ka ikaika, ka paʻakikī o ke apo make a me ka pono, ka maikaʻi o ka pelleting.I ka honua, koho pinepine ʻia ka mānoanoa (T) o ke apo make mai 32 ~ 127mm (ʻo ka mānoanoa liʻiliʻi ma Kina he 13mm).

ʻO ka lōʻihi maikaʻi o ka lua make pellet mill (L): ʻO ka lōʻihi o ka lōʻihi o ka lua make apo e pili ana i ka lōʻihi o ka lua make no ka extrusion mea (hana).ʻO ka lōʻihi o ka lōʻihi o ka lua make, ʻoi aku ka lōʻihi o ka manawa extrusion o nā mea i loko o ka lua make, ʻoi aku ka paʻakikī o nā pellets, a laila ʻoi aku ka maikaʻi o ka ikaika a me ka maikaʻi o nā pellets.ʻO ka mea ʻē aʻe, ua wehe nā pellets, kiʻekiʻe ka pulverization rate, a ua hoʻemi ʻia ka maikaʻi o ka pellet.

ʻO ke anawaena inlet tapered (D) o ka lua make: ʻoi aku ka nui o ke anawaena o ka lua hānai ma mua o ke anawaena o ka puka make (d), i mea e hōʻemi ai i ke kūʻē ʻana o ka mea i loko o ka lua, i mea e maʻalahi ai ke komo ʻana. i loko o ka lua make.Aiaʻekolu mauʻano o nā puka hānai,ʻo ia hoʻi ka puka pololei, ka puka cone a me ka puka curved. granulation.No kēia kumu, pono e hoʻolālā ʻia ka lua make i ʻelua ʻāpana, hānai extrusion pauku L a decompression hoʻokuʻu pauku R, ʻo ia hoʻi ʻo L+R=T.ʻEkolu mau ʻano kumu o ka puka decompression discharge: puka pololei, puka cone a me ka hui pū ʻana o ka puka cone a me ka puka pololei, ma waena o ka puka pololei a me ka puka cone ka mea maʻamau i hoʻohana ʻia, ʻoi aku ka nui o kona puka kiʻekiʻe ma mua o ke anawaena o ka puka make d. , hilinaʻi kona hohonu i ka lōʻihi hana kūpono L. I kekahi mau hihia, ʻoi aku ka nui o ka wā e ʻike ʻia ai ka mea hana i loko o ka lua kaomi hohonu e hoʻonui a hoʻopili ʻia, kūpono ke hoʻohana ʻana i ka hui hoʻololi o ka lua cone a me ka puka pololei, a i ʻole ka hoʻohana ʻana. o ka puka cone.