-

Smooth pelletizing machine roller shell

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

Through groove roller shell 1

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

Skewed tooth roller shell

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

Closed tooth roller shell

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

Combined hole and tooth

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

Honeycomb roller shell 1

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

Honeycomb roller shell 2

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

Through groove roller shell 2

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

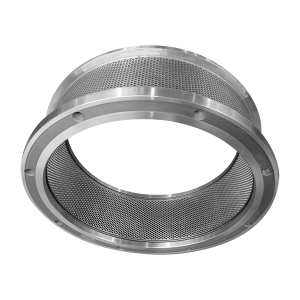

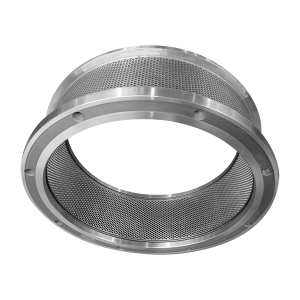

Agricultural Processing Equipment long Working Life Vertical Various Series ring Die Creep Muyang 600 Fish Feed Pellet Mill Die

Creep feed (commonly known as milk substitute, artificial milk), is a kind of feed pellet which replace the whole milk, its main raw material is dairy by-products. The nutritional index of substitute milk material is protein not less than 20%, fat is more than 6%. The particles are relatively fluffy and can be crushed with fingers. There are many factors that affect the quality of granule, among which the formula factor is dominant

-

Professional Manufacturer Directly Supply Ring Die Mould For Making Pig Feed Apply for Famsun Pellet Mill Die

As a key equipment in the feed production process, the heart of the pelletizing machine is the ring die (Zhengchang, Muyang, Shende), which is also one of the most easily worn parts in the pelletizing machine. For feed producers, it is urgent to reduce production costs and improve feed pellet quality, which is largely determined by the quality of ring die. Hanpai pig feed pellet mill die using high quality stainless steel material to ensure the long service life of the ring die,

-

Hoop

The blank is forged integrally. After rough machining, it is quenched and tempered. After quenching and tempering, it is refined. Then, the whole hoop is divided into three or four pieces of hoop. It is easy to use. It can provide hoop for CPM, Zhengchang, Buller, Shende and other pelletizers, and can also be processed according to drawings. -

factory directly supply agro processing equipment pellet mill spare parts roller shell

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.