Iprofayile yekhampani

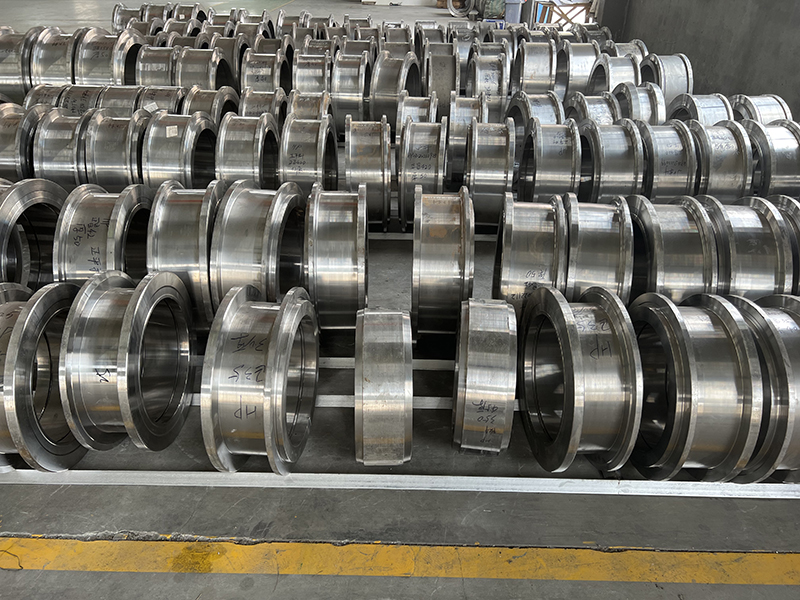

I-Hangzhou Hanpai Mold Technology Co. Ltd. yasekwa ngo-2012, liLungu leBhunga leZhejiang Die & Mould Industry Association.Siziingcali kwi-R & D kunye nokuveliswa kwamacandelo omatshini we-pellet, njenge-feed pellets ring die, i-biomass pellets ring die, iipellets zesichumisi se-organic. umsesane uyafa, inkunkuma yekati iipeliti ziyafa, iqokobhe le-roller njalo njalo.Ukubonelela nge-zero defect pellet mill die for the world yinjongo yethu yophuhliso.

Kunyaka wama-2017 siye sawongwa njengeshishini le-Hangzhou lobuchwepheshe obuphezulu kwaye saphumelela ukuvunywa kwephondo laseZhejiang amashishini ezenzululwazi kunye nobuchwepheshe.Ngo-2018, igama lenkampani yethu latshintshwa ukusuka ku-Hangzhou Hanpai Mold Co., LTD ukuya kwi-Hangzhou Hanpai Mold Technology Co., LTD.SinguMboneleli oPhicothiweyo ngu-SGS, ngoku sinesiqinisekiso senkqubo yolawulo lwe-ISO 9001.

Umngundo owonwabileyo usebenzisa umgangatho ophezulu we-X46Cr13 insimbi engenasici, umatshini weCNC wokugrumba umngxuma onzulu, ivacuum yokucima iziko, ezinye izixhobo eziphambili kunye nenkqubo eyodwa;Kwangaxeshanye sineqela lamagcisa akumgangatho ophezulu kunye nenkqubo engqongqo yolawulo lomgangatho wemveliso, nto leyo idala umgangatho ogqwesileyo weMold Mold kunye nereputation.Happy Mold ingenza ukusebenza kakuhle kwemveliso Ukunyusa i-10-40%, ixabiso lemveliso liyancipha 10 -40%

Ukonwaba Mold

"HAPPY MOULD" luphawu lwethu lwentengiso, ukusebenzisa i-Happy Mold kunokwenza umthengi agcine iindleko ezininzi zokuvelisa, ukwandisa inzuzo kunye nokhuphiswano lwemarike ngenxa yemveliso yayo egudileyo, umgangatho we-pellets olungileyo, ukusebenza kakuhle kwemveliso, ukusetyenziswa kwamandla aphantsi, kunye nokusebenza ngokulula. kunokunciphisa umfutho wabasebenzi, nto leyo izisa ulonwabo kumntu wonke.

IHanpai Mold iphumelele indumiso ebanzi kubathengi basekhaya nakwamanye amazwe, kwaye sijonge phambili ekuboneleleni ngokugqwesileyo kunye nokungabikho kokungunda kwesiphene kumashishini okuvelisa iipellet zehlabathi.

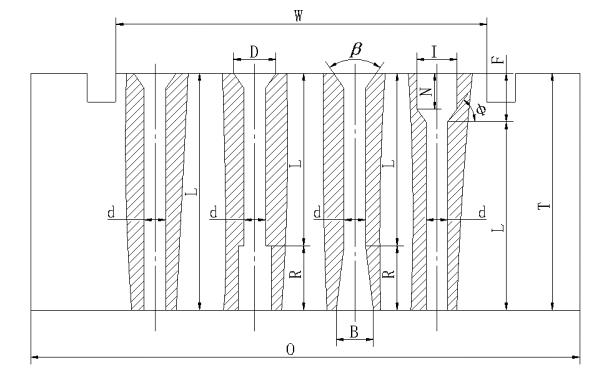

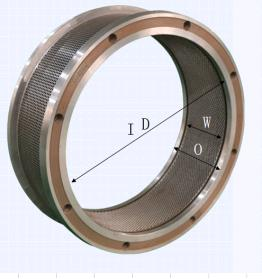

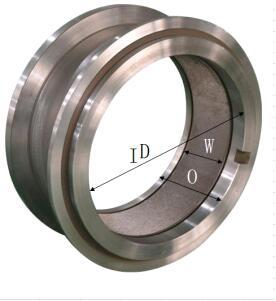

ID emfanekisweni -- idayamitha yangaphakathi yeringi yokufa;

O -- ububanzi bubonke bomsesane wokufa;

W -- ububanzi obusebenzayo bokufa kweringi (ububanzi bokusebenza komphezulu);

d -- umngxuma wokufa kweringi (ubungakanani bomngxuma wepellet ecinezelweyo);

L -- ubude obusebenzayo bomngxuma wokufa;

T -- ubuninzi obupheleleyo bomsesane uyafa;

D -- taper inlet ububanzi bomngxuma wokufa;

β -- kufa umngxuma conical inlet Iengile;

Imilo yomngxuma we-pellet yokusila iyafa: iimilo zomngxuma ezisetyenziswa ngokuqhelekileyo zibandakanya umngxuma othe tye, umngxuma wokubuyela umva, umngxuma wangaphandle wekhowuni yokubuyisela kunye nomngxuma wenyathelo lokuhamba phambili ngecone.Ukulungiswa komngxuma othe ngqo kulula, ukusetyenziswa okuqhelekileyo;Ubude obusebenzayo bomngxuma wokufa kunye nexesha lokukhutshwa kwezinto kwi-diye hong iyancitshiswa ngumngxuma wenyathelo elibuyela umva kunye nomngxuma we-taper wangaphandle, ilungele ukusetyenzwa kweepellets ezinobubanzi obungaphantsi kwe-φ10mm.Umngxunya wenyathelo lokuphinda uvuseleleke onemilo econical ilungele ukusetyenzwa kwesondlo se-pellet esinedayamitha engaphezu kwe-φ10mm enomxholo ophezulu wefiber ekrwada.Ukongeza kwiindidi ezi-4 zemilo yomngxuma, kukho iintlobo ngeentlobo zeemilo zomngxuma, ezinje ngomngxuma ongaphandle we-conical, umngxuma wangaphakathi wekhowuni kunye nomngxuma ongekho setyhula, kodwa ukusetyenziswa akuqhelekanga.

R -- ubunzulu bokubuyisela umva (umngxuma wokukhulula uxinzelelo);

B -- idayamitha yokubuyisela umva (umngxuma wokukhulula uxinzelelo);

φ -- i-engile yokutshintsha okuqinisekileyo;

F -- ubunzulu bokubuyisela kwakhona;

I-i-diameter evumayo yokubuyisela kwakhona;

L / d -- ubude-umlinganiselo wokuvula (umlinganiselo woxinzelelo).

Ukutyeba kwe-pellet mill die (T) : Ubunzima bokufa kweringi buchaphazela ngokuthe ngqo amandla, ukuqina komsesane wokufa kunye nokusebenza kakuhle, umgangatho wepellet.Ehlabathini, ubukhulu (T) bomsesane wokufa budla ngokukhethwa ukusuka kwi-32 ~ 127mm (ubukhulu obuncinci e-China buyi-13mm).

Ubude obusebenzayo bomngxuma wokusila we-pellet (L) : Ubude obusebenzayo bomngxuma wokufa weringi bubhekisa kubude bomngxuma wokufa wezinto ezikhuphayo (ukwenza).Ubude obusebenzayo bomngxuma wokufa, ixesha elide lokukhutshwa kwezinto kwi-diye hole, i-pellets ilukhuni, ngoko amandla kunye nomgangatho we-pellets ungcono.Ngokuchasene noko, iipelisi zikhululekile, izinga le-pulverization liphezulu, kwaye umgangatho we-pellet uyancipha.

I-tapered inlet diameter (D) yomngxuma wokufa: ububanzi bomngxuma wokutya kufuneka ube mkhulu kunobubanzi bomngxuma wokufa (d), ukuze kuncitshiswe ukuxhathisa kwezinto emngxunyeni, ukuze kube lula ukuba bangene. kumngxunya wokufa.Kukho iindlela ezintathu ezisisiseko zemingxuma yokutya, ezizezi, umngxuma othe tye, umngxuma wekhowuni kunye nomngxuma ogobileyo. Kwizinto eziluhlaza ezinomxholo ophezulu wefayibha, ngenxa yomahluko weempawu zegranulation, kuyafuneka ukunciphisa ukuchasana ngomngxuma wokufa kwinkqubo igranulation.Ngenxa yesi sizathu, umngxuma wokufa kufuneka uyilwe ube ngamacandelo amabini, icandelo le-feed extrusion L kunye necandelo lokukhutshwa kwe-decompression R, oko kukuthi L+R=T.Kukho iindlela ezintathu ezisisiseko zokukhupha umngxuma wokuthotywa: umngxuma othe tye, umngxuma wekhowuni kunye nokudityaniswa komngxuma wekhowuni kunye nomngxuma othe tye, phakathi kwawo umngxuma othe tye kunye nomngxuma wekhowuni zezona zisetyenziswa ngokuqhelekileyo, indawo yayo yokuvula ingaphezulu kancinci kunomngxuma wokufa d. , ubunzulu bayo buxhomekeke kubude obusebenzayo obuhambelanayo obusebenzayo L. Kwezinye iimeko, ngakumbi xa izinto zokucubungula zibonakala kumngxuma onzulu woxinzelelo ziya kwanda kunye neplagi, kufanelekile ukusebenzisa inguqu yenguqu yomngxuma wekhowuni kunye nomngxuma othe tye , okanye ukusetyenziswa. yomngxuma wekhowuni.