umzi-mveliso unikezela ngokuthe ngqo izixhobo zokusetyenzwa kwe-pellet yokusila iinxalenye zerola

umzi-mveliso unikezela ngokuthe ngqo izixhobo zokusetyenzwa kwe-pellet yokusila iinxalenye zerola

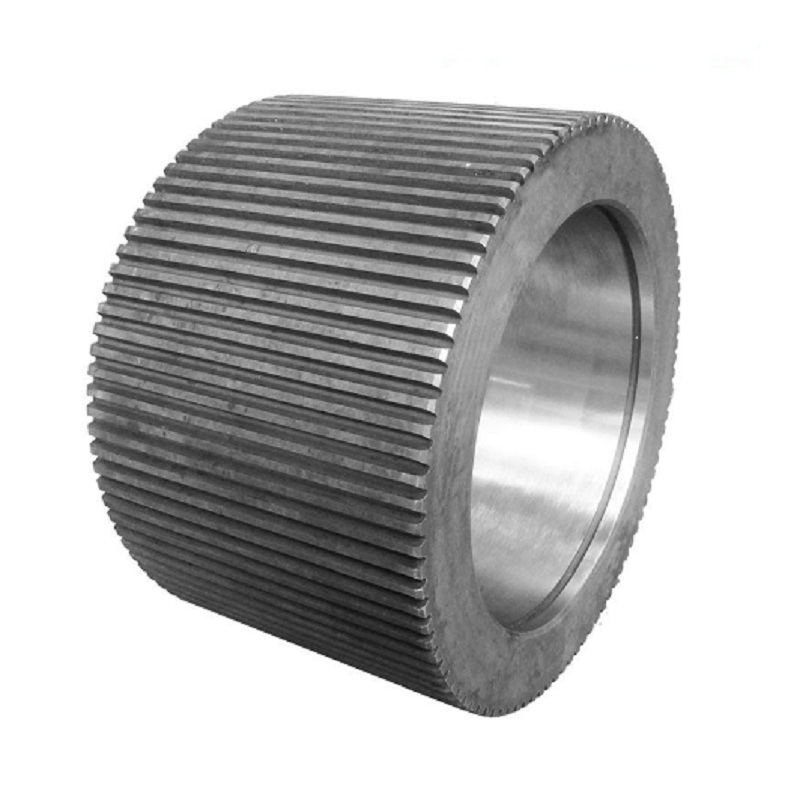

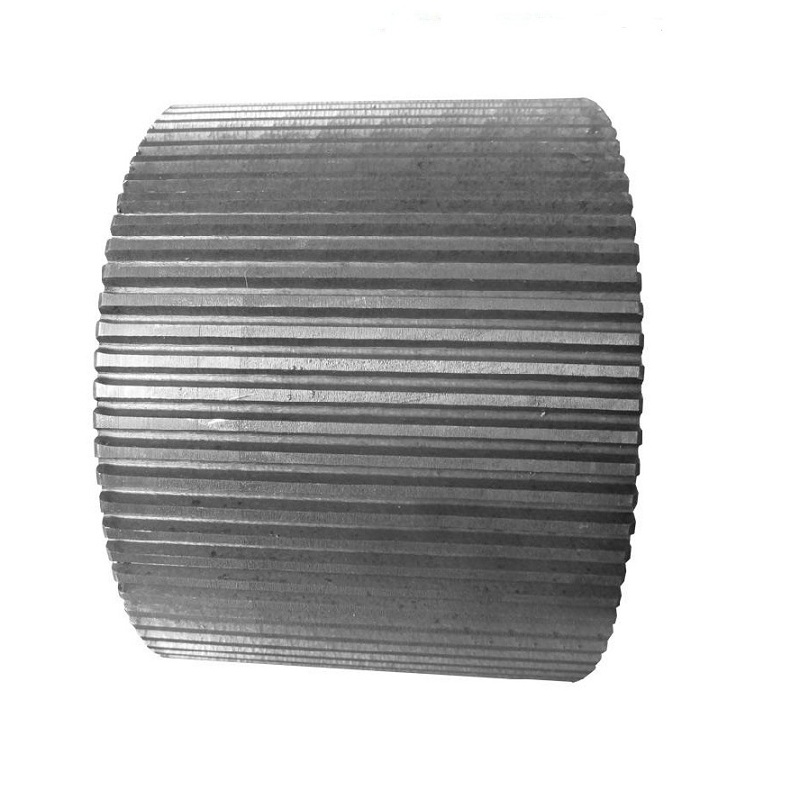

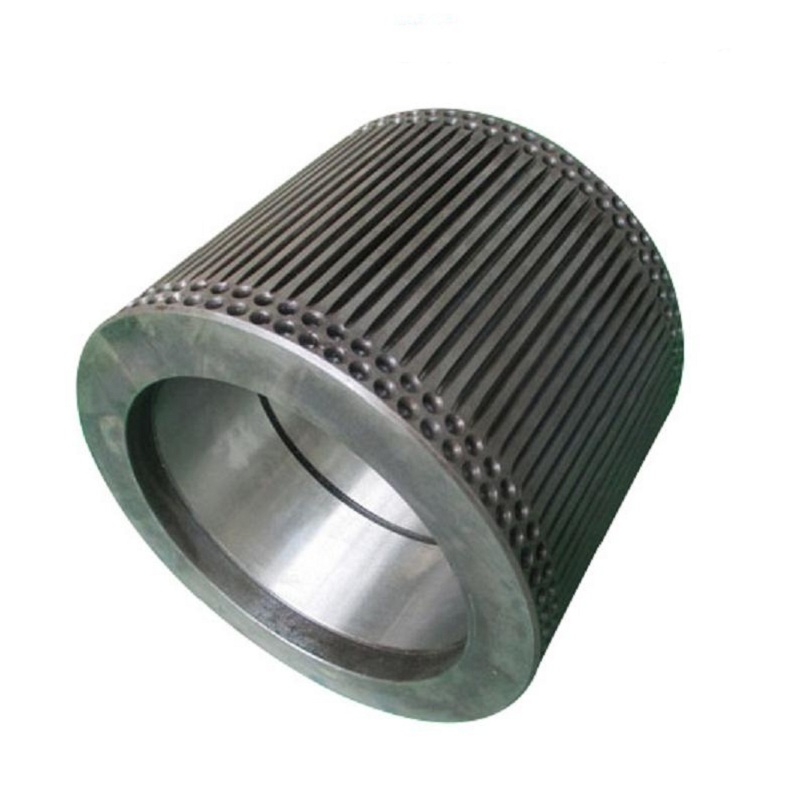

I-roller shell yenkampani yethu yenziwe ngezinto ezikumgangatho ophezulu kunye nokulungiswa kobushushu obukhethekileyo.Umphezulu wayo unxiba ngakumbi kwaye ubulukhuni bufana, zidityaniswe ne-Happy Mold ring die, ubomi benkonzo buya kuba bude, emva koko wenze imveliso ikhuseleke kwaye igudiswe. iindidi.Ubukhulu obuhlukeneyo kunye neemilo zeerola zingenziwa ngokwezifiso ngokwemfuno yomsebenzisi.

Iiparamitha zokuchazwa kweqokobhe eliqengqelekayo:

Izinto eziphathekayo: Gcr15 okanye 40Cr 20CrMnTi

Idayamitha yangaphandle ye-workpiece: Ø300mm-1200mm

Ukuqina komphezulu: HRC 58-62

Indawo yamazinyo kunye nokumila: Ngokweemfuno zabathengi

Indlela echanekileyo yokusebenzisa idayi yeringi kunye neqokobhe lerola

1. Ukhetho oluchanekileyo lomngxuma wokufa weringi efanelekileyo kunye nomlinganiselo woxinzelelo.

2. Ukulungelelanisa ngokuchanekileyo i-gap yokusebenza phakathi kwe-ring ring kunye ne-press roll, phakathi kwe-0.1 ~ 0.3mm ifanelekile.

3. Idiyizi entsha yeringi kufuneka isetyenziswe kunye neqokobhe lerola elitsha.Iqokobhe le-roller kufuneka likhululeke ngaphambi kwaye liqine emva kokuhambelana nomsesane wokufa.Xa iikona ezibukhali zivela kumacala omabini e-press roller, inxalenye ye-flange ye-press roll kufuneka igudiswe kunye ne-grinder yesandla ngexesha, ukwenzela ukuba kube lula ukuhambelana kakuhle phakathi kwe-press roll kunye ne-ring ring.

4. I-raw material kufuneka icutshungulwe phambi kokuba ingene kwigranulator ngokucoca kwangaphambili kunye nokwahlulwa kwamagnetic ukunciphisa ucinezelo lwentsimbi kumngxuma wokufa.Kwaye ukujonga umngxuma wokufa rhoqo ukubona ukuba kukho into ethintelayo.Gubha ngaphandle okanye ukhuphe umngxuma wokufa ovalekileyo ngexesha.

5. Ring die guide cone umngxuma utshintsho iplastiki eyenziwe ukushwabana kufuneka zilungiswe, ukulungiswa kufuneka ingqalelo kumphezulu wangaphakathi umsesane die ukusebenza kwindawo esezantsi kufuneka ibe phezulu kunomzantsi groove 2mm, kwaye emva kokulungiswa kusekho a cofa i-eccentric shaft adjustment margin, kungenjalo i-ringe yokufa kufuneka ichithwe.