Iphrofayela Yenkampani

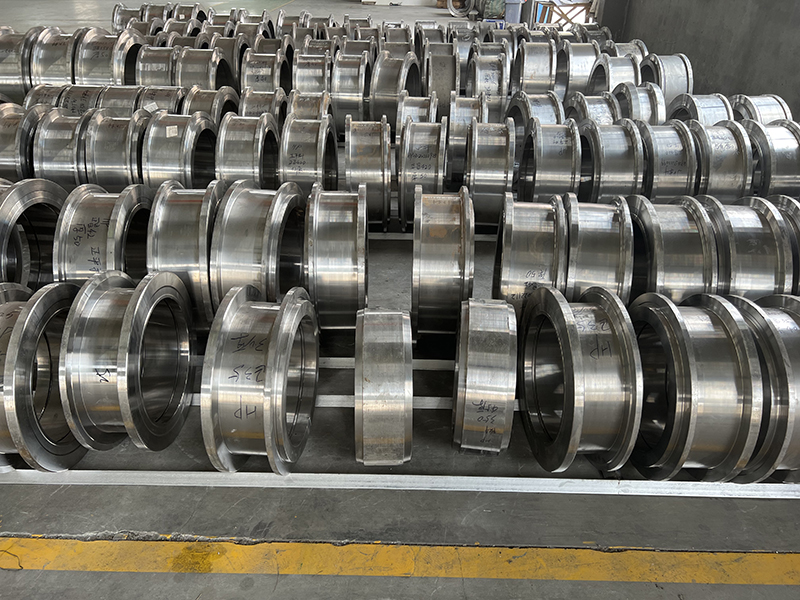

I-Hangzhou Hanpai Mold Technology Co. Ltd. yasungulwa ngo-2012, iyiLungu LoMkhandlu le-Zhejiang Die&Mould Industry Association.Sisebenza ngokukhethekile kwi-R&D kanye nokukhiqizwa kwezingxenye zomshini wokugaya, njenge-feed pellets ring die, biomass pellets ring die, ama-organic fertilizer pellets. ring die, cat udoti pellets ring die, roller shell nokunye.Ukuhlinzeka nge-zero defect pellet mill die for the world kuwumgomo wethu wokuthuthukisa.

Ngonyaka wezi-2017 sahlonishwa njengebhizinisi le-Hangzhou high-tech futhi saphasisa ukugunyazwa kwesifundazwe saseZhejiang amabhizinisi ezesayensi nezobuchwepheshe.Ngo-2018, igama lenkampani yethu lashintshwa lisuka ku-Hangzhou Hanpai Mold Co., LTD laya ku-Hangzhou Hanpai Mold Technology Co., LTD.Singabahlinzeki Bempahla Abahloliwe yi-SGS, manje sesinesitifiketi sohlelo lokuphatha ikhwalithi ye-ISO 9001.

I-Happy Mold isebenzisa insimbi engagqwali engu-X46Cr13 yekhwalithi ephezulu, umshini wokumba imbobo ejulile ye-CNC, isithando somlilo esivala ivacuum, enye imishini ethuthukisiwe nenqubo eyingqayizivele;Ngesikhathi esifanayo sineqembu lochwepheshe bezinga eliphezulu kanye nesistimu yokulawula ikhwalithi yokukhiqiza eqinile, edala ikhwalithi enhle kakhulu ye-Happy Mold kanye nedumela elihle lekhasimende.I-Happy Mold ingenza ukusebenza kahle kokukhiqiza Kwenyuke ngo-10-40%, izindleko zokukhiqiza zehle ngo-10 -40%

Isikhunta esijabulisayo

I-"HAPPY MOULD" uphawu lwethu lokuthengisa, ukusebenzisa i-Happy Mold kungenza ikhasimende lisindise izindleko eziningi zokukhiqiza, likhulise inzuzo kanye nokuncintisana kwemakethe ngenxa yokukhiqiza kwayo okubushelelezi, ikhwalithi ye-pellets enhle, ukusebenza kahle kokukhiqiza okuphezulu, ukusetshenziswa kwamandla okuphansi, nokusebenza okulula. kunganciphisa umfutho wabasebenzi, okuletha injabulo kuwo wonke umuntu.

I-Hanpai Mold izuze ukunconywa okubanzi kumakhasimende asekhaya nakwamanye amazwe, futhi sibheke ngabomvu ukuhlinzeka ngesikhunta esihle kakhulu nesingenasici kumabhizinisi okukhiqiza ama-pellet omhlaba.

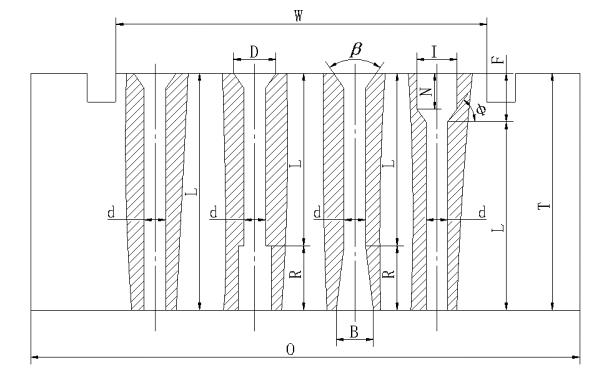

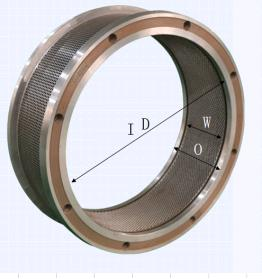

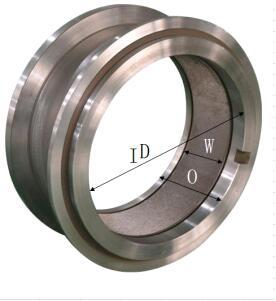

I-ID emfanekisweni -- ububanzi bangaphakathi bokufa kwendandatho;

O -- ububanzi obuphelele bokufa kwendandatho;

W - ububanzi obusebenzayo bokufa kwendandatho (ububanzi bendawo yokusebenza);

d -- indawo yokuvula indandatho (usayizi womgodi we-pellet ecindezelwe);

L -- ubude obusebenzayo bomgodi wokufa;

T -- ukushuba okuphelele kwendandatho iyafa;

D -- taper inlet ububanzi bomgodi wokufa;

β -- imbobo yokufa ye-conical inlet angle;

Umumo wembobo we-pellet mill uyafa: izimo zembobo ezivame ukusetshenziswa ikakhulukazi zihlanganisa imbobo eqondile, imbobo yesinyathelo esibuyela emuva, imbobo yokubuyisela ikhoni yangaphandle kanye nembobo yesinyathelo sokuguqula phambili enekhoni.Ukucubungula imbobo eqondile kulula, ukusetshenziswa okuvame kakhulu;Ubude obusebenzayo bembobo yokufa kanye nesikhathi sokukhipha impahla emgodini wokufa sincishiswa imbobo yesinyathelo esibuyela emuva kanye nembobo ye-taper yangaphandle, ifanele ukucubungula ama-pellets ngobubanzi obungaphansi kuka-φ10mm.Imbobo yesinyathelo sokuvuselela kabusha enomumo oyiconical ifaneleka ukucubungula okuphakelayo kwe-pellet okunobubanzi obungaphezu kuka-φ10mm obunokuqukethwe okuphezulu kwefiber engahluziwe.Ngaphezu kwalezi zinhlobo ezi-4 ezingenhla zomumo wembobo, kunezinhlobonhlobo zezimo zembobo, njengembobo yekhoni yangaphandle, imbobo yekhoni yangaphakathi kanye nomgodi ongewona oyindilinga, kodwa ukusetshenziswa akuvamile.

R -- ukujula kokuhlehla kabusha (imbobo yokukhulula ingcindezi);

B -- ububanzi bokubuyisela emuva (imbobo yokukhulula ingcindezi);

φ -- I-engeli yokuguqula kabusha okuhle;

F -- ukujula kabusha okuphozithivu;

I -- i-diameter yokubuyisela kabusha ephozithivu;

L/d -- ubude bokuvula isilinganiso (isilinganiso sokucindezela).

Ubukhulu be-pellet mill die (T): Ubukhulu bendandatho yokufa buthinta ngqo amandla, ubulukhuni bendandatho yokufa kanye nokusebenza kahle, ikhwalithi ye-pelleting.Emhlabeni, ukujiya (T) kwedayizi lendandatho kuvame ukukhethwa ukusuka ku-32 ~ 127mm (ubukhulu obuncane e-China bube ngu-13mm).

Ubude obusebenzayo be-pellet mill die hole (L) : Ubude obusebenzayo bembobo yokufa eyindandatho bubhekisela kubude bembobo yokufa ye-extrusion (ukwakheka).Ubude obusebenzayo bembobo yokufa, isikhathi eside sokukhipha impahla emgodini wokufa, ama-pellets enziwa nzima, khona-ke amandla kanye nekhwalithi yamapellets kungcono.Ngokuphambene nalokho, ama-pellets akhululekile, izinga le-pulverization liphezulu, futhi izinga le-pellet liyancipha.

I-tapered inlet diameter (D) yembobo yokufa: ububanzi bomgodi wokuphakela kufanele bube bukhulu kunobubanzi bembobo yokufa (d), ukuze kuncishiswe ukumelana kwento embobeni, ukuze kube lula ukuthi bangene. emgodini wokufa.Kunezinhlobo ezintathu eziyisisekelo zezimbobo zokudla, okuyimbobo eqondile, imbobo yekhoni kanye nembobo egobile.Ngezinto ezingavuthiwe ezinokuqukethwe okuphezulu kwe-fiber, ngenxa yomehluko wezimpawu zegranulation, kuyadingeka ukunciphisa ukumelana ngokusebenzisa imbobo yokufa ngesikhathi imbudumbudu.Ngenxa yalesi sizathu, imbobo yokufa kufanele iklanywe ibe izingxenye ezimbili, ingxenye ye-feed extrusion L kanye nesigaba sokukhipha ukucindezela u-R, okuyi-L+R=T.Kunezinhlobo ezintathu eziyisisekelo zembobo yokukhipha i-decompression: imbobo eqondile, imbobo yekhoni kanye nenhlanganisela yembobo yesigaxa kanye nembobo eqondile, phakathi kwayo imbobo eqondile kanye nembobo yekhoni isetshenziswa kakhulu, imbobo yayo ephezulu ikhudlwana kancane kunobubanzi bomgodi wokufa d , ukujula kwayo kuncike kubude obusebenzayo obuhambisanayo obusebenzayo L. Kwezinye izimo, ikakhulukazi lapho izinto zokucubungula zivela emgodini wengcindezi ejulile zizokhula futhi zixhumeke, kufanelekile ukusebenzisa inhlanganisela yenguquko yembobo yesigaxa kanye nembobo eqondile , noma ukusetshenziswa we-cone hole.