ifektri ihlinzeka ngokuqondile ngemishini yokucubungula i-agro ye-pellet mill spare parts roller shell

ifektri ihlinzeka ngokuqondile ngemishini yokucubungula i-agro ye-pellet mill spare parts roller shell

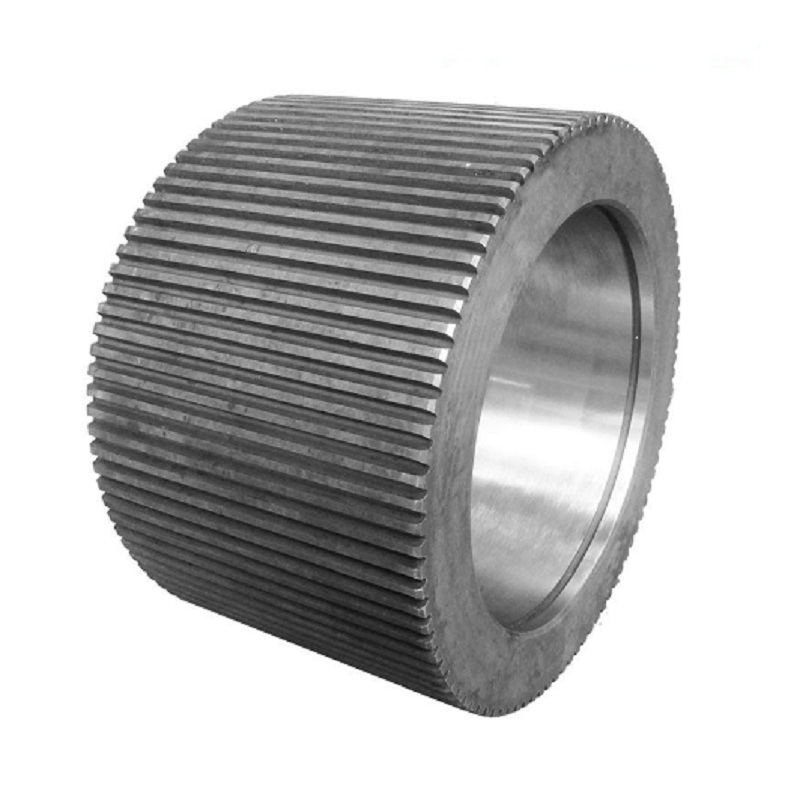

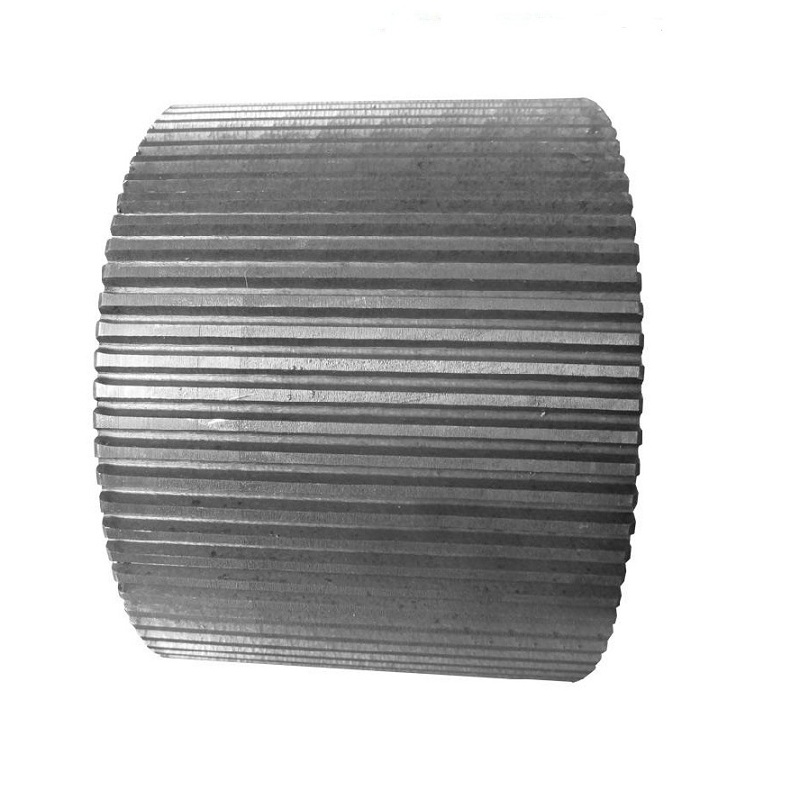

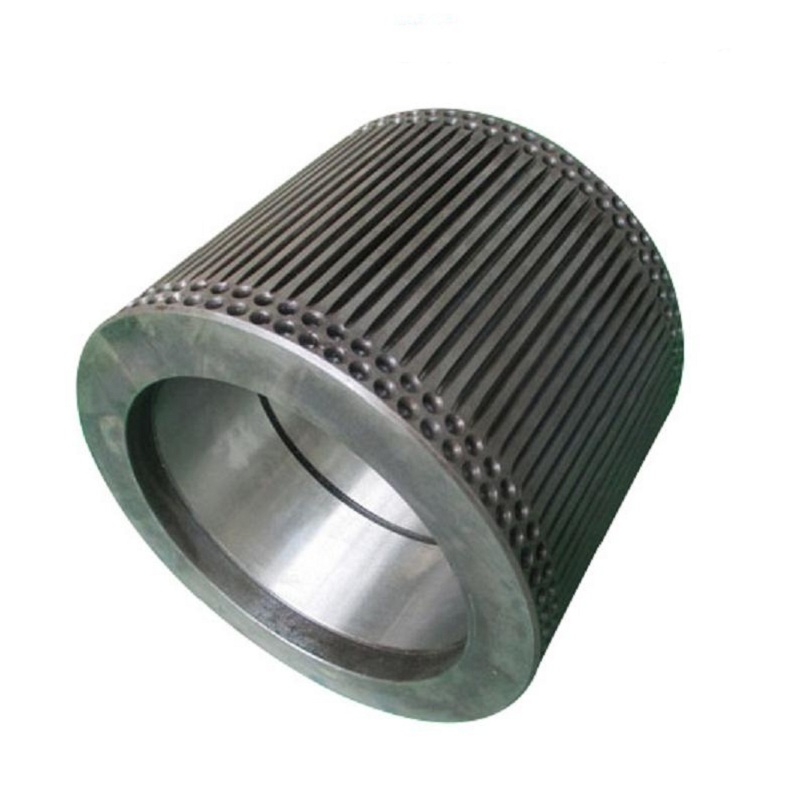

Igobolondo le-roller yenkampani yethu lenziwe ngezinto ezisezingeni eliphezulu kanye nokucubungula okukhethekile kokwelashwa kokushisa.Ubuso bayo bugqokwa kakhulu futhi ubulukhuni bufana, kuhlanganiswe nendandatho ye-Happy Mold, impilo yesevisi izoba yinde, bese yenza ukukhiqizwa kuphephe futhi kube bushelelezi. izinhlobo.Ubukhulu obuhlukene kanye nokubunjwa kwama-roller kungenziwa ngokwezifiso ngokusho kwesidingo somsebenzisi.

Imininingwane ye-roller shell:

Impahla: Gcr15 noma 40Cr 20CrMnTi

Ububanzi bangaphandle be-workpiece: Ø300mm-1200mm

Ukuqina kobuso: HRC 58-62

Isikhala samazinyo nokuma: Ngokwezidingo zekhasimende

Indlela elungile yokusebenzisa idayi yeringi kanye negobolondo le-roller

1. Ukukhetha okulungile kwembobo yokufa eyindandatho efanele kanye nesilinganiso sokucindezela.

2. Lungisa kahle igebe lokusebenza phakathi kwe-ring ring kanye ne-press roll, phakathi kuka-0.1~0.3mm kufanelekile.

3. Idayi yeringi entsha kufanele isetshenziswe negobolondo lerola elisha.Igobolondo le-roller kufanele likhululeke ngaphambi futhi liqine ngemva kokuhambisana nedayizi leringi.Uma amakhona abukhali avela ezinhlangothini zombili ze-roller yokucindezela, ingxenye ye-flange ye-press roll kufanele ibe bushelelezi nge-grinder yesandla ngesikhathi, ukuze kube lula ukufana okuhle phakathi kwe-press roll kanye nokufa kwendandatho.

4. Impahla eluhlaza kufanele icutshungulwe ngaphambi kokufaka i-granulator ngokuhlanzwa kokuqala kanye nokuhlukaniswa kazibuthe ukuze kuncishiswe ukucindezelwa kwensimbi emgodini wokufa.Futhi ukuhlola imbobo yokufa njalo ukuze ubone ukuthi kukhona yini into evimbelayo.Khipha noma ubhoboze imbobo yokufa evinjiwe ngesikhathi.

5. I-ring die guide cone imbobo yokuguqulwa kwepulasitiki eyenziwe kufanele ilungiswe, ukulungiswa kufanele kunake indawo engaphakathi yendandatho esebenza endaweni ephansi kakhulu kufanele ibe ngaphezu kwe-2mm ngaphansi kwe-groove, futhi ngemva kokulungiswa kusekhona cindezela i-eccentric shaft adjustment margin, ngaphandle kwalokho umucu weringi kufanele uchithwe.